Please select items that can be sterilized using filtration. Filtration sterilization is a method of sterilizing liquids and gases by passing them through a filter that removes microorganisms. This method is commonly used in the pharmaceutical, food and beverage, and medical device industries.

Filtration sterilization is a relatively simple and cost-effective method of sterilization. It is also a very effective method, as it can remove even the smallest microorganisms from liquids and gases.

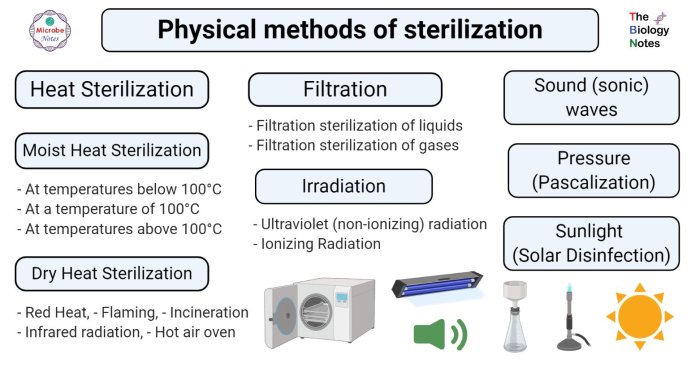

Filtration Sterilization

Filtration sterilization is a method of sterilizing liquids and gases by passing them through a filter with pores small enough to trap microorganisms but large enough to allow the passage of the fluid or gas. Filtration sterilization is a reliable and effective method for removing bacteria, viruses, and other microorganisms from a wide range of fluids and gases.

Sterilization Methods, Please select items that can be sterilized using filtration

Filtration sterilization is a physical method of sterilization that involves passing a fluid or gas through a filter with a pore size that is small enough to trap microorganisms but large enough to allow the passage of the fluid or gas.

The filter material can be made of a variety of materials, including cellulose, glass fiber, or ceramic.

The principle of filtration sterilization is based on the size of microorganisms. Bacteria are typically 0.5-10 µm in size, while viruses are typically 0.02-0.3 µm in size. Filters used for sterilization typically have pore sizes of 0.2 µm or smaller, which is small enough to trap even the smallest viruses.

Filtration sterilization is a relatively simple and inexpensive method of sterilization. It is also a very effective method, as it can remove 100% of microorganisms from a fluid or gas.

Applications of Filtration Sterilization

Filtration sterilization is used in a variety of industries and applications, including:

- Pharmaceutical industry

- Food and beverage industry

- Cosmetic industry

- Medical industry

- Water treatment industry

Filtration sterilization is suitable for a wide range of liquids and gases, including:

- Water

- Alcohols

- Oils

- Gases

Some specific examples of products or materials that are sterilized using filtration include:

- Pharmaceuticals

- Food and beverages

- Cosmetics

- Medical devices

- Water

Factors Affecting Filtration Sterilization

The effectiveness of filtration sterilization is affected by a number of factors, including:

- Filter pore size

- Fluid flow rate

- Temperature

- Filter material

- Pretreatment steps

Filter pore size is the most important factor affecting the effectiveness of filtration sterilization. The smaller the pore size, the more effective the filter will be at removing microorganisms.

Fluid flow rate also affects the effectiveness of filtration sterilization. The higher the flow rate, the more likely it is that microorganisms will be able to pass through the filter.

Temperature can also affect the effectiveness of filtration sterilization. The higher the temperature, the more likely it is that microorganisms will be killed by the heat.

Filter material can also affect the effectiveness of filtration sterilization. Some filter materials are more effective at removing microorganisms than others.

Pretreatment steps can also affect the effectiveness of filtration sterilization. Pretreatment steps, such as filtering the fluid or gas through a prefilter, can help to remove large particles that could clog the filter.

Validation and Monitoring

It is important to validate the effectiveness of filtration sterilization processes to ensure that they are removing 100% of microorganisms from the fluid or gas. Validation can be done by using a variety of methods, including:

- Biological indicators

- Physical indicators

- Chemical indicators

It is also important to monitor filtration sterilization processes on a regular basis to ensure that they are continuing to operate effectively. Monitoring can be done by using a variety of methods, including:

- Pressure gauges

- Temperature gauges

- Flow meters

Safety and Regulatory Considerations

Filtration sterilization is a safe and effective method of sterilization. However, there are some safety and regulatory considerations that should be taken into account when using this method.

One safety consideration is the potential for filter failure. Filter failure can occur if the filter is not properly maintained or if it is used to filter a fluid or gas that is too hot or too cold.

Another safety consideration is the potential for contamination of the fluid or gas after it has been sterilized. Contamination can occur if the filter is not properly handled or if the fluid or gas is not stored in a sterile container.

There are a number of regulatory requirements that apply to filtration sterilization in different industries. These requirements vary depending on the industry and the specific application.

It is important to be aware of the safety and regulatory considerations associated with filtration sterilization before using this method.

FAQ Guide: Please Select Items That Can Be Sterilized Using Filtration

What is filtration sterilization?

Filtration sterilization is a method of sterilizing liquids and gases by passing them through a filter that removes microorganisms.

How does filtration sterilization work?

Filtration sterilization works by trapping microorganisms on the surface of a filter. The pores of the filter are small enough to prevent microorganisms from passing through, but large enough to allow liquids and gases to pass through.

What are the advantages of filtration sterilization?

Filtration sterilization is a relatively simple and cost-effective method of sterilization. It is also a very effective method, as it can remove even the smallest microorganisms from liquids and gases.

What are the disadvantages of filtration sterilization?

Filtration sterilization can be time-consuming, especially for large volumes of liquids or gases. It can also be difficult to validate the effectiveness of filtration sterilization.